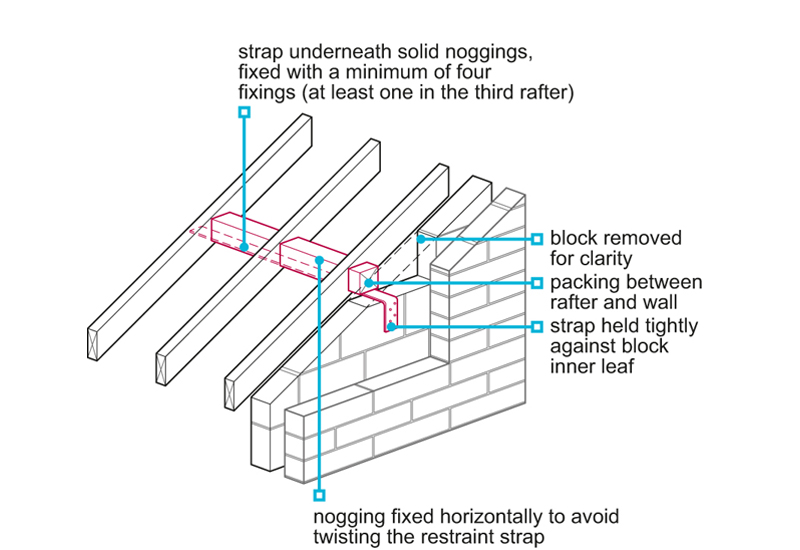

Fixing to solid noggings using four 50mm minimum x 4mm steel screws or four 75mm x 4mm 8swg round nails with one fixing in the third rafter fig 7 2 8 or.

Fixing roof restraint straps.

Straps should span a minimum of three rafters joists with at least one fixing in.

Be galvanised with a minimum cross section of 30mm x 5mm 2.

Lateral restraint straps should be fixed to the roof structure by either.

Fixing to longitudinal bracing members using eight 25mm x 4mm steel screws evenly distributed along the length.

Fixing to solid noggings using a minimum of four 50mm x 4mm steel screws or four 75mm x 4mm 8swg round nails with one fixing in the third rafter figure 1 or.

It is important to note that while most manufacturers state that heavy duty straps are 5mm thick they will most likely be between 4mm and 5mm and tending to be more towards 4mm.

Hooked over a solid block screw fixing to face of blocks is not acceptable.

The straps are produced from edge coated galvanised mild steel also available in stainless steel.

Enjoy watching and keep yours eyes peeled.

We did something different with this how to video and filmed it as we was working and having a chat.

Heavy duty straps are used for horizontal restraint of roof joists trusses or rafters attached onto masonry walls.

Have noggins between rafters joists with packing between the wall and first member.

Light duty restraint strap 600mm twisted 100mm.

0 71 0 85 inc vat galvanised light duty restraint strap 600mm twisted 100mm is designed for vertical restraint for example fixing wall plates to masonry.